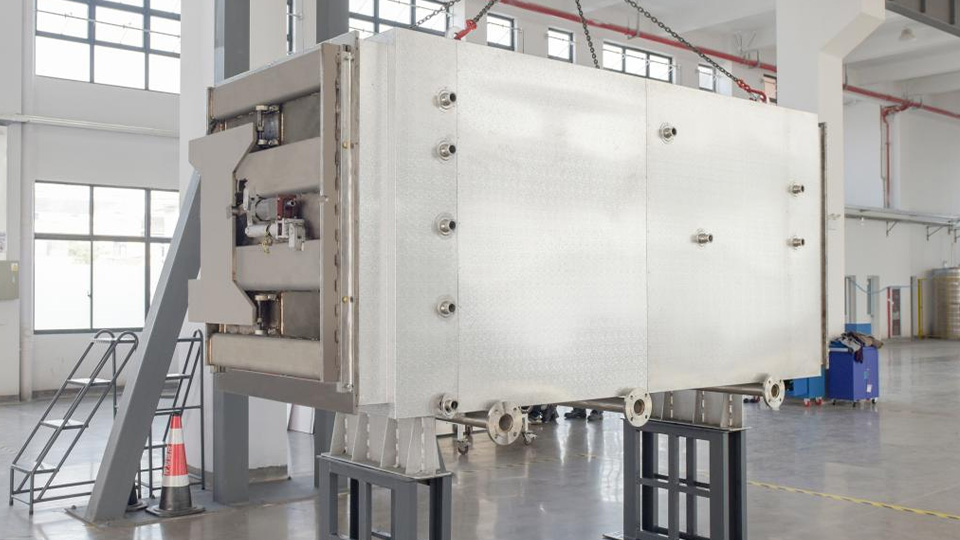

Sophisticated Design

The design and manufacture of chamber conforms to the following regulations and standards:

China Standard:

Pressure Vessel Safety Technology Supervision Regulations, Special Equipment Manufacturing License of the People's Republic of China

European Standard:

2014/68/EU New Pressure Equipment Directive

American Standard:

ASME Boiler & Pressure Vessel Code, Section VIII, Division 1.